BioDiamond

The Facts

The BioDiamond Stent is a remarkable improvement over existing stents, concerning its thrombogenicity, biocompatibility and design. The stent is constructed for high flexibility and low recoil. The stainless steel stent is coated by an advanced coating process, which results in a homogenous covering of the metal surface of the stent with a diamond-like layer. This results in a reduced thrombogenicity and enhanced biocompatibility. In short, the improvements are given below. A more detailed description you may read on the following pages. For navigation please use the left frame or the bar at the bottom of this page.

"The BioDiamond stent design meets the demand and the wishes of international cardiologists. The BioDiamond stents show a large improvement over existing stents. The thinner wall does not result in an enhanced recoil of the stent (shown by Prof. Schmitz, Rostock). The BioDiamond stents have a recoil of about 3-4 %. In literature an average recoils between 3% - 20% are reported for stents on the market."

"The tests concerning thrombogenicity, biocompatibility and structure meet the demands claimed in the essay of Yukio Ozaki, et. al. 1996 Future Stents" (45).

"Diamond-like coated surfaces show only minimal adhesion of proteins. Furthermore, those adhesions are reversible and do not result in denaturations of protein. Inflammation will not take place at these surfaces (66-70)".

"Diamond-like coated stainless steel stents show almost zero release of chromium and nickel ions even after 44 hour immersion in 1 N Hydrochloric Acid".

"The "time for stent occlusion" is significantly extended using diamond-like coated or heparin plus diamond-like coated stainless steel stents".

"The strongest thrombocyte activation occurred with the uncoated stainless steel stents. The diamond-like stainless steel stents or the diamond-like steel stent coated with heparin proved to be a significant lower activation of thrombocytes".

Diamond-Like Coated Stainless Steel Stents

It is well known from the literature, that diamond-like surface coatings on stainless steel and plastics surfaces enhances the biocompatibility and hemocompatibility of these materials dramatically (42, 59, 62-70). Diamond-like surfaces could be synthesized since the early 60's and the material is well defined and described for medical implants like peacemakers etc. (72-88).

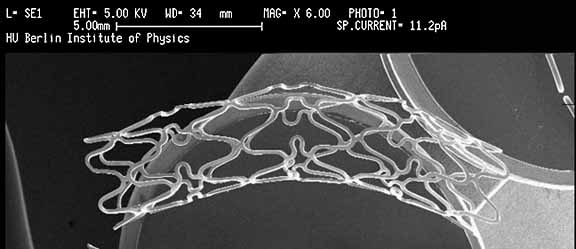

To coat the inner lumen of a stent, a special technique is required, for the Faraday's law does not allow a plasma, which is the key for the generation of diamond-like surfaces, to be generated in the inner lumen of a tube. The BioDiamond diamond-like coated stainless steel stent is the first stent which is produced by coating the inner and the outer walls of the stent with a diamond-like carbon film layer.

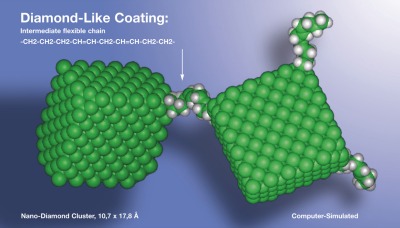

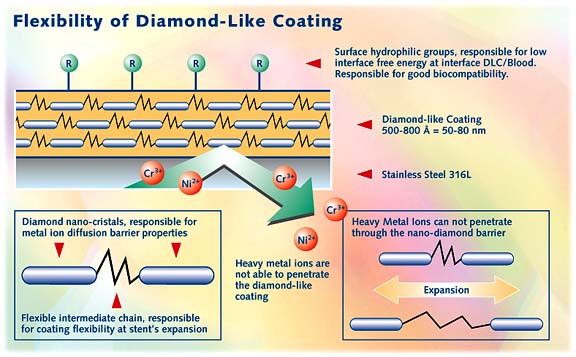

Stainless steel is a highly thrombogenic material due to the release of mainly nickel and chromium ions. It is well known from literature that the stainless steel 316 L used as implants release free chromium and nickel ions which are able to destroy or damage enzymes and proteins (93). Furthermore it is known that these chromium and nickel ions can aggravate allergies. So most of the directions for implants include warnings concerning chromium and nickel allergies. The diamond-like coated surface of the BioDiamond stent builds up a barrier against the heavy metal ions diffusion of nickel and chromium ions into the surrounding tissue and the blood stream (71).

The first step in building up a thromb after stent implantation is the adsorption of proteins on the stent surface. As more proteins are adsorbed, as sooner the development of a thromb could be observed (56-58). Diamond-like coated surfaces show only minimal adhesion of proteins at the surface (63-70). Furthermore those adhesions are reversible and do not result in denaturations of protein which lead to the presentation of antigens on the stent surface. Inflammation will not take place at these surfaces.

It could be shown by flow cytometric experiments, that relevant thrombocytic antigens will be expressed in a significant lower amount on thrombocytes after contact with diamond-like coated surfaces compared with uncoated surfaces. It could be demonstrated, that the time for stent occlusion (TSO) is much more enhanced with a diamond-like coated stent surface compared to an uncoated one. Thrombocytes adhere to diamond-like coated stent surfaces in a much more reduced way than they adhere to uncoated stainless steel stent surfaces. This results in a much more reduced risk of stent occulation after implantation of the BioDiamond diamond-like coated stainless steel stents.

The BioDiamond stent design meets the demand and the wishes of international cardiologists. The BioDiamond stents show an large improvement over existing stents. The thinner wall of the BioDiamond stent does not result in an enhanced recoil of the stent. The BioDiamond stent has a recoil of about 3% - 4%. In literature average recoils between 4% - 20% are reported for stents on the market. Also by coating the BioDiamond stent with a diamond-like carbon film layer, the micro roughness of the stent surface is drastically reduced and the stent has an excellent hydrodynamic behaviour.

High Flexibility combined with High Stability and Low Recoil

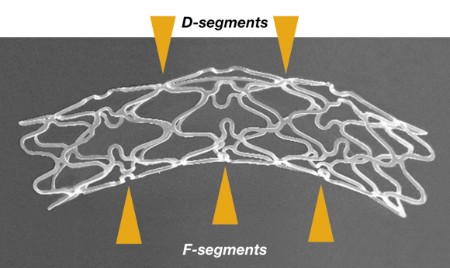

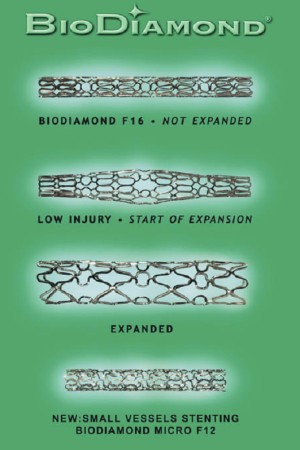

In the Biodiamond F stent family flexible F-segments and dense D-segments combine longitudinal flexibility with high radial strength and low recoil (< 4 %).

Reduced Risk of Thorn and Cutting Trauma by profiled Walls and Highly Reproducible Production Process

- The specially developed BioDiamond electropolishing process generates a specific profile of wall thickness, which along with the specific design allows the start of expansion from the middle to the flanks. This avoids the "Thorn" - trauma of the aorta intima by "pins" located at the both end of the stent.

- BioDiamond electropolishing guarantees a highly reproducible precision in wall thickness with a deviation of ± 5-8 µm in comparison to the state of the art with an accuracy of ± 15-25 µm. Advantage: Higher reproducibility and reliability during cardiologic intervention.

- Thin stent walls allow the use of high surface density of stent elements and thus the decrease of the specific pressure of stent elements on vessel walls during deployment, and decreasing the risk of a "cutting" trauma.